Wave Soldering as a manufacturing process

Wave Soldering Wave soldering is a process where components or connection elements are bulk soldered onto the PCB after they are placed on the board. The technique is mainly used for THT components but SMD components can also be soldered using wave soldering.

What is Wave Soldering?

Wave soldering is also known as wave soldering. It is a manufacturing process used for soldering a larger number of printed circuit boards.

The benefits of THT

The Through Hole Technology has several advantages. It is a very reliable technology. There is a strong connection between the circuit board and all the components. Because of this, many manufacturers still like to use Through Hole Technology. Within applications where a circuit board is mechanically loaded and under increased stress, Through Hole Technology is a widely used technique.

The Process of Wave Soldering

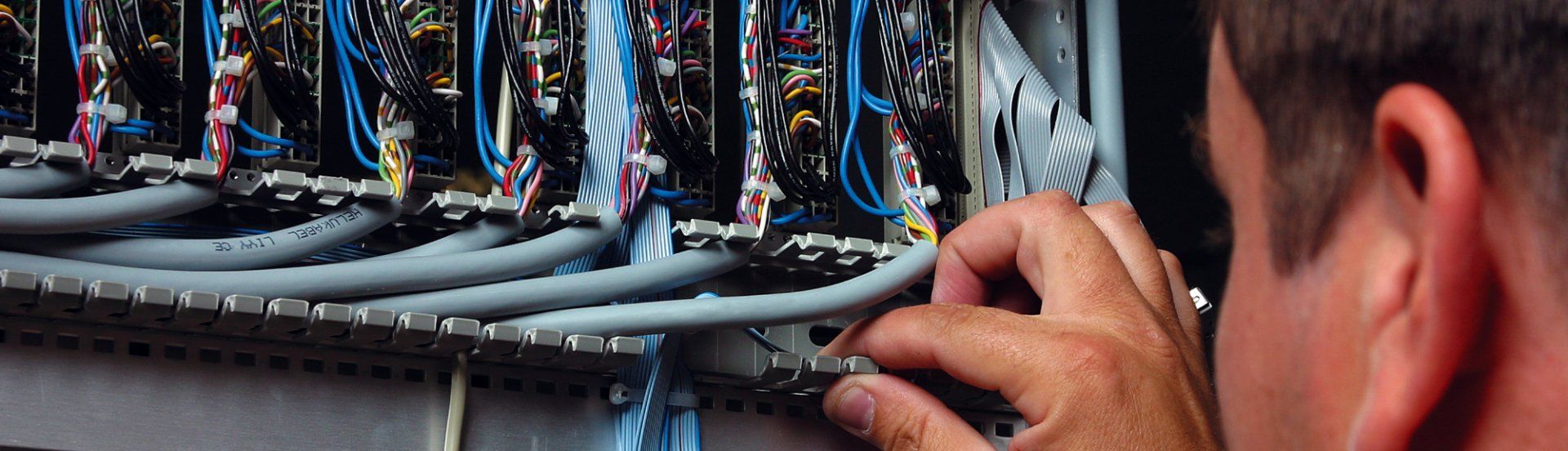

Wave Soldering involves moving a circuit board over a bath of molten solder, in which there is a pump that can cause a stirring up of the solder. This phenomenon resembles a kind of standing wave, hence the name wave soldering. Contact is made between the solder and the circuit board and thus the components are soldered to the board. Then the temperature is brought down in a controlled manner so that the components are properly fixed to the board. The correct temperature is very important for this process, if the temperature is not controlled correctly it will inevitably lead to quality problems such as cracking and loss of conductivity. The wrong temperature can also cause the viscosity of the solder to be incorrect. This can cause the joints to show abnormalities when the board is subjected to mechanical stress.

Wave Soldering and PCB Assembly

Wave Soldering is applied within PCB assembly. Confed can help you with your PCB projects when it comes to design, prototyping and series production of your PCBs. The whole process can thus be taken out of your hands using all leading techniques, from the beginning to the end. Work is always done efficiently, but also carefully and quickly.

The complete focus here is always on customer needs. PCBA techniques such as Surface Mounting and Through Hole are also applied within Confed. Every challenge in the field of industrial controllers and controllers gets the attention it needs from us. We are at your service for small to large series.

Choose Confed. Choose fast, reliable and quality.

Got curious?

Have you become curious about what we can do for you in this area? We would like to invite you to contact us. This can easily be done by phone or via our general email address. You can also send us a request via the contact page and we will get back to you as soon as possible.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340