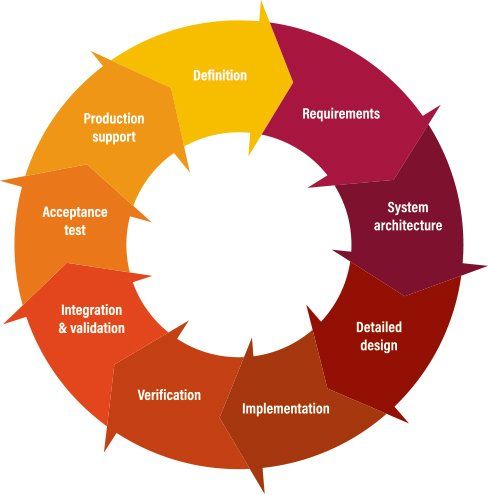

Confed's development department, Confed Solutions, specializes in designing smart products. Our expertise focuses on embedded systems, products in which hardware, embedded software and firmware come together. We help clients throughout the product life cycle of their product. Most projects start with a definition of the product's features and then go through the entire cycle until the product is ready for serial production. If a concept is already developed, we can also start at a later stage. Projects are often carried out in collaboration with the customer in some form of co-development.

Definition of properties and set of requirements

In the first phase, together with the client, we arrive at a definition of the characteristics of the product and a set of requirements. In addition to the functional requirements, we also look at non-functional issues such as performance, compliance with legal (CE) requirements, environmental conditions, etc.

If the technical feasibility or principles of the product are not clear, we can start by conducting a Proof of Concept or feasibility study.

Choice of system architecture

Once the starting points are known, work starts on determining the system architecture. The functions of the product are broken down, considerations are made in terms of make or buy, hardware and software, microcontroller/FPGA, etc. Appropriate component choices are made for the main functions, the necessary interfaces are chosen, and at the software level, the architecture is determined which includes determining whether an RTOS, Linux or bare metal implementation will be used. In addition, the form factor of the product is considered, showing whether a division into physical modules is necessary.

The architecture is recorded in an Architectural Design Document (ADD).

Elaboration of detail design

During the detailed design, a distinction is made between the various disciplines. For each discipline, the design is further developed in detail. The results of the design are recorded for each discipline.

Software detail design

To define the software, we use the Software Detailed Design (SDD) document. Following the architecture, in this phase we describe what the structure of the code is.

Hardware detail design

This phase produces a Hardware Detailed Design document (HDD) that defines the design considerations. In performing the detailed hardware design, the required components are selected for all functions. Electronic circuits are also designed during this phase. Topics covered further include simulations, thermal aspects, thermal management and EMC filtering.

Interface detail design

Interfaces exist within a product in several areas. The Interface Detailed Design (IDD) document describes how the interface works but also how the interface can be used.

Housing design

To protect the electronics from environmental factors, various housing options can be chosen, such as a customer-specific housings or a selection of one of the standard housings, and whether or not to encapsulate in synthetic resin. Confed plays an advisory role in this process. Considerations included in the choice are appearance, cost price, production numbers, IP classification, robustness.

Implementation

During the implementation phase, the elaborated design is executed as described in the detailed design phase.

Software implementation

Based on the defined functional blocks, the implementation of the software is now performed, the actual coding of the software. Depending on the project, we use the programming language that best suits the requirements of the project. To support the development of the code, we use different tools. We use a version control system (SVN/GIT) and an automated build and test environment (Continuous Integration / Continuous Delivery).

Hardware Implementation

Using the hardware design document as a starting point, the electrical schematic is now drawn using Altium Designer. As with the software implementation, the complete hardware design is also stored in a version control system, and relationships are recorded with the issue trackers' used.

Prototype construction

After completing the hardware implementation, 1 or more prototypes of the product are built. The implementation can be done by our Protoshop coordinated.

Verification, validation and acceptance testing

In this phase, it is verified that the implementation has been done correctly. With the prototype, the sub-circuits are checked in detail. Thus, we assess whether the prototype meets the defined functionality. The results of the tests are recorded in a test report.

The next step is the integration between hardware and software. The purpose of these tests is to verify that the entire product meets the properties described in the system architecture.

Acceptance testing verifies that the product meets the requirements described in the Requirements Document. For all test phases, any deviations in the design are recorded. Before the design is released to production, all recorded deviations are incorporated into the design.

Production support

Transfer to production

When the design is ready for series production, Technical Product Documentation (TPD) is delivered describing how the product is to be assembled. This information includes such things as Gerber/ODB++ files, parts lists, bestucking drawings, PCB specifications, assembly instructions and 3D models. With this data, production resources are prepared to assemble a limited 0-series. These 0-series products can then be deployed by the customer for field testing.

Production test systems

In order to check during production that the correct quality has been produced, different types of production test systems are used. The chosen test strategy depends on production volumes, complexity of the product. Often a functional test system based on a pin bed is used. The design of the test system can be carried out by Confed Solutions.

Support during the production phase

Once the 0-series is complete and the production test systems are validated, production can be scaled up. The design team remains available for support during the production phase. This includes advice on applying second sources for components and support during production testing.

Got curious?

Are you curious about what we can do for you with our development department?

If so, please contact Hans van Eijck, Confed's CCO. You can find his contact information on our team page.

As an existing relationship, you can of course also contact your own account manager.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340