What does Designed for testing mean?

Designed for Testing (DFT) consists of a set of design techniques that add test functions to a printed circuit board design. These added features aim to facilitate the testing of (assembled) printed circuit boards and thus reduce the cost of testing.This can result in a reduction of:

- The time spent on testing

- The cost associated with generating the test vectors

- The number of design iterations required to achieve acceptable test coverage or yield.

The purpose of Designed for Testing (DFT)

The purpose of testing is to validate that the assembled circuit board does not contain manufacturing defects that could adversely affect the correct operation of the product.

Testing can be applied at various steps in the manufacturing process and, for certain products, can also be used for hardware maintenance in the customer's environment. Tests are generally driven by test programs performed using automatic test equipment (ATE) or, in the case of system maintenance, within the assembled system itself. In addition to finding and indicating the presence of defects (i.e., the test fails), tests can potentially record diagnostic information about the nature of the abnormalities found. The diagnostic information can be used to locate the cause of the failure.

In other words, the response of vectors (patterns) from a good circuit is compared to the response of vectors (with the same patterns) from a DUT (device being tested). If the response is the same or matches, the circuit is good. Otherwise, the circuit is not manufactured as intended.

DFT plays an important role in test program development and as an interface for test application and diagnostics. Automatic generation of test patterns, or ATPG, is much easier when proper DFT rules and suggestions are implemented.

Some techniques are very simple, such as applying resets to a design. Without these resets, test vectors must perform a homing sequence that puts a design into a known state so that testing can actually begin.

More typical is the introduction of scan-based testing, built-in self-test (BIST) or increased observability with JTAG. Most test circuitry is introduced after synthesis, although BIST techniques are often integrated into the functionality of the block. Early analysis can be performed during the RTL design phase to identify design decisions that may affect the testability of the design.

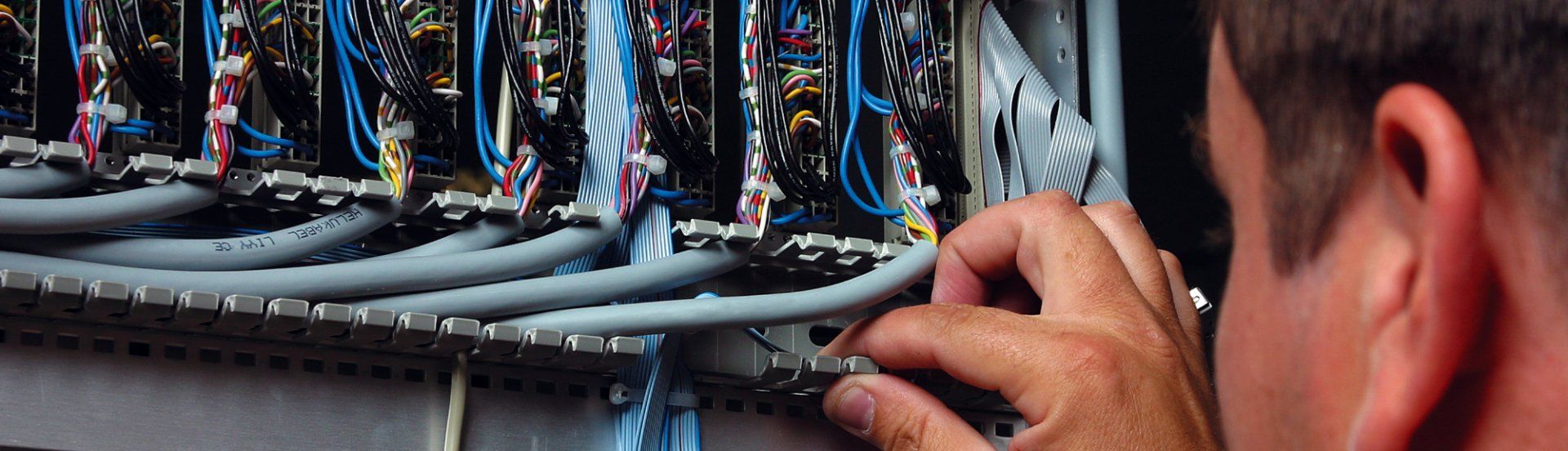

Designed for Testing at Confed

Our specialists within various disciplines have extensive experience and knowledge regarding the design, development and testing of products. They will advise and think along with you at all times in the process.

At Confed, it is important to us that we deliver quality products, without manufacturing defects or flaws. Designed for testing is therefore crucial before we hand the products over to the assembly team or user.

Want to learn more about Designed for Testing at Confed and what the possibilities are for you? Please contact us. We will be happy to answer your questions and think about solutions with you.

Choose Confed. Choose fast, reliable and quality.

Got curious?

Have you become curious about what we can do for you in this area? We would like to invite you to contact us. This can easily be done by phone or via our general email address. You can also send us a request via the contact page and we will get back to you as soon as possible.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340