What is the difference between "Cut Tape" and "Tape and Reel?

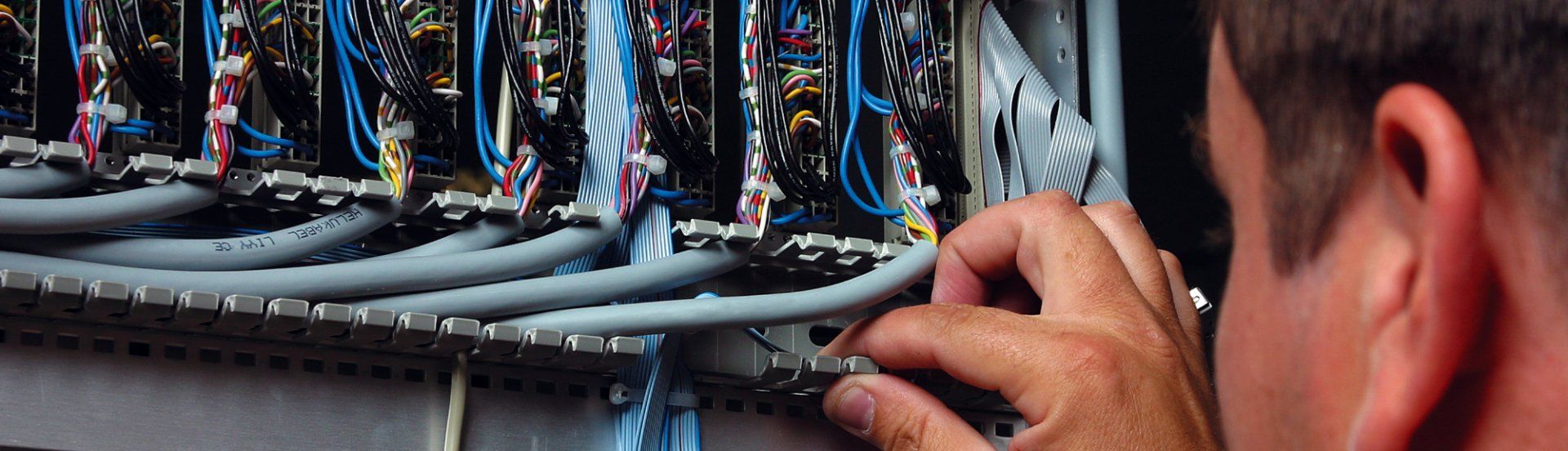

At Confed, we are working every day to discover new innovative technologies that both reduce PCB production time and lower costs. We have fully automated SMD lines standing for PCB assembly, also called placement machines. They are capable of placing tens of thousands of components per hour with great placement accuracy and the certainty of a correct connection. These components can be packaged and delivered in a variety of ways, and this is where these terms come into play.

Cut Tape and Tape and Reel are both packaging types used for SMT components. Cut tape and Tape and Reel are both methods in which components are placed on a tape. This allows the components to be supplied via automatic feeders during the placement process. In this blog, we will discuss the differences and advantages between and of cut tape and tape from a reel.

The use of Reel and Cut Tape

During the procurement of Surface-Mount Technology (SMT) components, it is important to pay attention to the packaging type. The type of packaging depends on the loading preferences which in turn depend on factors such as batch sizes, size and price. There are several options for this, such as cut tape, reel, tray, tube and batch. Each type has its advantages and may be more suitable for one component than another. The two main packaging types are cut tape and tape from a reel.

Cut tape, or cut tape, is the method in which components are placed on plastic tape that is cut into strips. A strip of tape can contain from 10 to hundreds of components.

Reel tape, or tape from a spool, is the method in which components are placed on tape that is wound back into a spool.

A reel can hold 400 - 100,000 components. The major difference between Cut Tape and Tape and Reel is the length; with smaller numbers of components, a cut tape piece comes in with components, with tape and reel it is about the larger numbers and the tape (which is much longer) comes in on a reel.

The difference between Reel and Cut tape

Thus, the main difference between cut tape and reel tape is the length. Through cut tape, components are placed on strips of tape. Each strip can contain hundreds of components. If the need for component increases and thus the length of the tape becomes longer, the tape is wrapped around a spool for that reason. A spool is often chosen because it can be loaded faster. It is more efficient to load a spool than an individual stroke of tape. The choice between the two options is made based on considerations of batch size, price, multi-deployability, etc.

Reel and Cut Tape for Quality

There are several factors that determine the best packaging type for the SMT components in question. These include component complexity, order volume, time-to-market, and cost efficiency.

Here are the benefits of Cut tape:

- Suitable for lower volumes;

- Suitable for short-term PCB assembly and prototyping.

The benefits of Reel tape:

- Suitable for high volumes;

- Easy to use;

- Less time spent loading.

Reel and Cut tape at Confed

At Confed, we believe it is important to coordinate for each individual PCB project which packaging type best suits your needs and requirements. For some projects this may be cut tape and for others it may be tape from a spool. Are you curious about or have questions about the packaging type that is most suitable for your project? Feel free to contact us and our specialists will be ready to think with you.

Choose Confed. Choose fast, reliable and quality.

Got curious?

Have you become curious about what we can do for you in this area? We would like to invite you to contact us. This can easily be done by phone or via our general email address. You can also send us a request via the contact page and we will get back to you as soon as possible.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340