What is a PCB test fixture?

Any electronic product, no matter how well designed, is prone to errors and irregularities. It is therefore essential to thoroughly test electronic products, and in this particular case PCBs, right from the first stage of design. This testing of PCBs at the design level can be done through various techniques such as EMI, Signal Integrity and Power Integrity. This minimizes design issues that can lead to problems later on. But how can you test a PCB after it has been assembled to verify that all is okay? How can you be sure there are no latches, bad solder joints or misplaced components? In this blog we would like to explain what test methods are for this and how Confed deploys and develops these test methodologies for its customers.

What is a PCB test fixture?

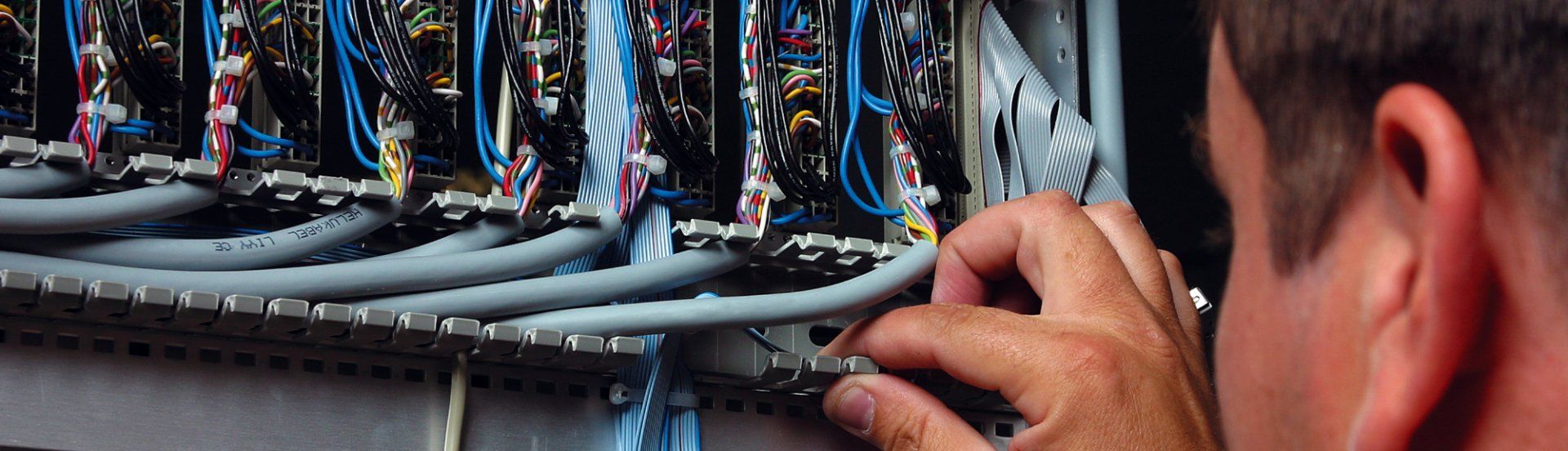

In general sitting, you can say that a PCB test fixture is a device which consists of pin bed with which a PCB (loose or already assembled) can be tested. These test fixtures can be operated manually or pneumatically. Manual operation requires the user to operate the fastener that holds the PCB in place on the pin bed so that the test can be performed. With pneumatic operation, this operation is performed automatically.

Test fixtures are custom designed for specific PCBs or a product line of PCBs. In the design of the PCB, this way of testing is taken into account beforehand, among other things by drawing in test points so that the testing of the PCB on the fixture can be carried out as productively as possible.

The different ways to perform a PCB test fixture

A PCB test fixture can be performed in different ways and at different stages. We briefly explain these different methods below.

A bare-board PCB test

A bare-board PCB test fixture is a test that tests (still) empty boards. Here, the defined circuit connection is correctly verified on the fabricated PCB.

Thus, a small voltage is applied to the board and verified that the board functions properly on the terms ''short'' or ''open.''

An assembly-level PCB test fixture

Assembled PCBs can also be thoroughly tested. This can be done in a variety of ways. For example, a manual inspection or just an Automatic Test Equipment (ATE) can be used. An ATE performs a PCB test much faster than when performed manually. However, an ATE is much pricier than a manual test. For this reason, it is necessary to choose the right type suitable for PCB testing.

A functional PCB test

A Functional Test (FCT) is the final testing step in the PCB development process. It provides a pass/fail determination on finished PCBs before they are delivered. The purpose of the FCT is to validate that the hardware is free of defects that could interfere with the correct operation of the product.

A PCB test fixture at Confed

Confed has years of experience and knowledge in designing, assembling and testing PCBs. We perform various test fixtures at our own discretion (to prevent defects) or at the request of our customers.

Would you like to know more about the different PCB test fixtures? Feel free to contact us without obligation. We will answer your questions and think along with you.

Choose Confed. Choose fast, reliable and quality.

Got curious?

Have you become curious about what we can do for you in this area? We would like to invite you to contact us. This can easily be done by phone or via our general email address. You can also send us a request via the contact page and we will get back to you as soon as possible.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340