Slide title

Project

Examples

Projectvoorbeelden

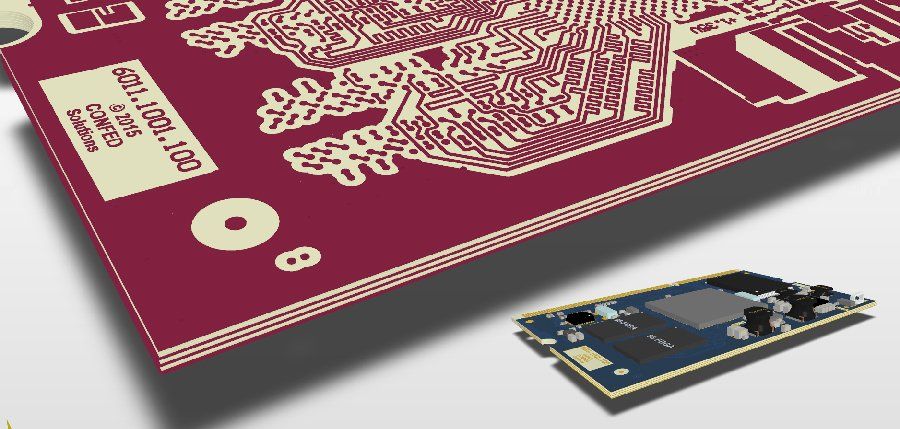

For this project, the time/material project approach was used. The client could not set hard specifications beforehand but wanted to be able to realize the best technically feasible specifications in a small form factor. We started with several Proof of Concepts to arrive at an architecture choice. Once the platform was chosen, in this case a Xilinx FPGA, we looked at partitioning into multiple PCBs to make the product as compact as possible. It was decided to use flex-rigid technology for some boards so that they could be optimally positioned, and no loose cables were needed.

To achieve a compact assembly of the PCB with the FPGA, it is equipped with double-sided bestucking.

Features:

- compact form factor

- high-speed interfaces

- high voltage (200V) circuits

- analog circuits

- design of multiple complex circuit boards

Technologies:

- flex-rigid PCB

- FPGA (Xilinx Artix)

- High Density Interconnect (HDI) PCB: 12 layer, blind + buried vias, laser drilled vias

- high speed design: USB 3.0, Gigabit Ethernet, LVDS

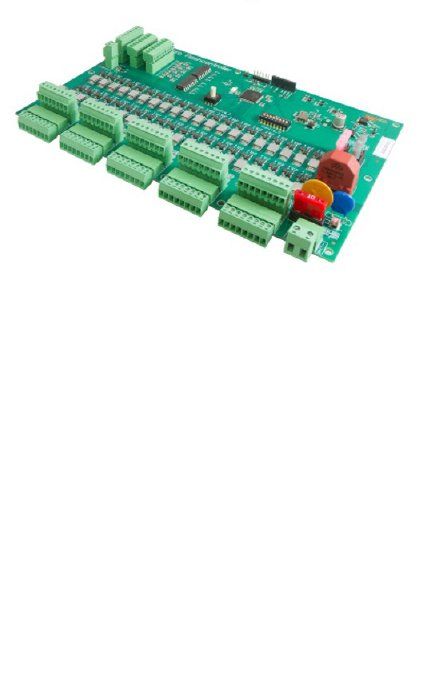

This product is characterized by being used in an automotive environment. The design must withstand the requirements set forth in ISO 7637.

EFeatures:

• robust design

• control via remote control unit

Technologies:

• ARM cortex M0

• load dump protection

For this application, an interface to an existing Keysight VME control card had to be realized.

Features:

• interface to VME control card

• integration into 19" rack housing

Technologies:

• FPGA

• BiSS C protocol support

• VME bus

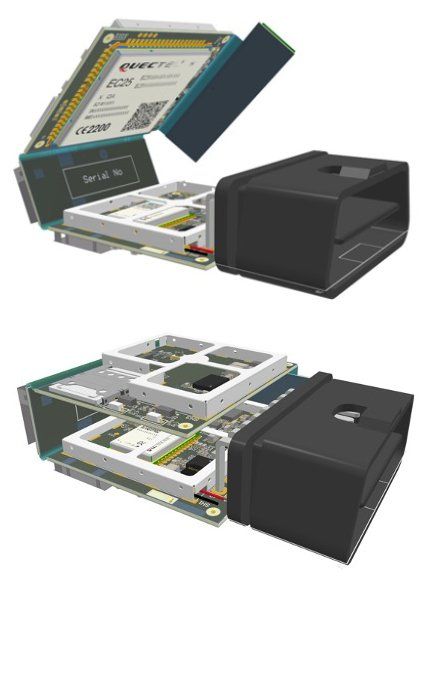

Lots of functionality, low cost and a compact product. These were the principles with which the design started. To realize this, flex-rigid PCB technology was used. This made a compact construction possible, and in addition, the 3 antennas needed could each be placed on a different surface in the room. Custom shielding was designed in collaboration with a partner.

Features:

• automotive application

• various sensors

• custom shielding

• compact design

• 3 antennas on-board

Technologies:

• flex rigid PCB

• LTE modem

• GPS

• Wifi

• OBD

The client of this project was looking for a new platform, to be applied in a new generation of products. Existing System on Modules did not meet the technical features and cost requirements.

Hence, the choice was made to design an SoM ourselves.

Eigenschappen:

• platform designed to customer specification

• SO-DIMM form factor

• focus on Signal Integrity

Technologies:

• ARM cortex A7

• DDR3 memory

• NAND flash storage

• Linux

• Interfaces: LVDS, HDMI, SATA, Ethernet, USB

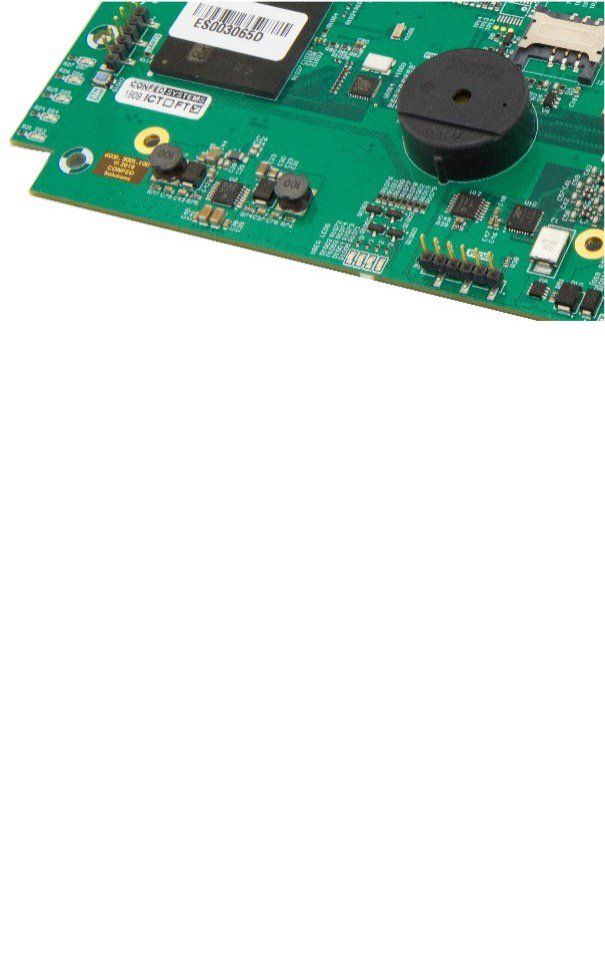

Initially, we used a SingleBoardComputer, in this case a BeagleBoneBlack, for this application. The required functionality of the product came to sit on a simple expansion board placed under the SBC.

After the product had been on the market for several years, we integrated the functionality of the SBC with the functions of the expansion board into a single circuit board. At that time, the design of this board immediately became a lot more complex with the use of DDR3 memory and eMMC flash, among others.

A next step was to apply an Octavo SystemInPackage. This SIP consists of a single BGA that integrates the CPU, DDR3, eMMC and power management functions. This step allowed us to reduce the parts list by about 170 components. An additional benefit of this revision is that it eliminated a number of "troublesome" components with short life cycles. This allowed us to significantly extend the product life cycle.

Features:

• platform from SBC to SIP

• migration GPRS/LTE-M/LTE

• design housing in cooperation with partner

Technologies:

• CPU platform: ARM cortex A8, DDR3, eMMC

• Linux

• Octavo System In Package

• LTE cat M network

• TFT display

Got curious?

Have you become curious about what we can do for you with our engineering department?

If so, please contact Marcel Lentfert, Confed's CTO. You can find his contact information on our team page.

As an existing relationship, you can of course also contact your own account manager.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340