What is the SMT process like?

When people talk about the SMT process, they are talking about a technology related to printed circuit boards. It is an assembly technique that relates to the placement of components on printed circuit boards. This technique is increasingly being used because it provides low costs due to increased productivity. With SMT technique, the components and elements are applied directly to the surface of the PCB. This is in contrast to the conventional technique where components are applied through hole through the PCB, known as Through Hole Technology (THT). This SMT technique provides much higher placement speeds compared to the THT technique.

What does the term SMT (Surface Mounting Technology) mean?

SMT stands for Surface Mounting Technology. This technology was developed in the 1960s and its use increased greatly during the 1980s. Using this technology, the industry has been able to greatly increase the number of placements per hour of components on a circuit board. For example, speeds of 40,000 placements using SMT technology are very common today.

How does SMT work?

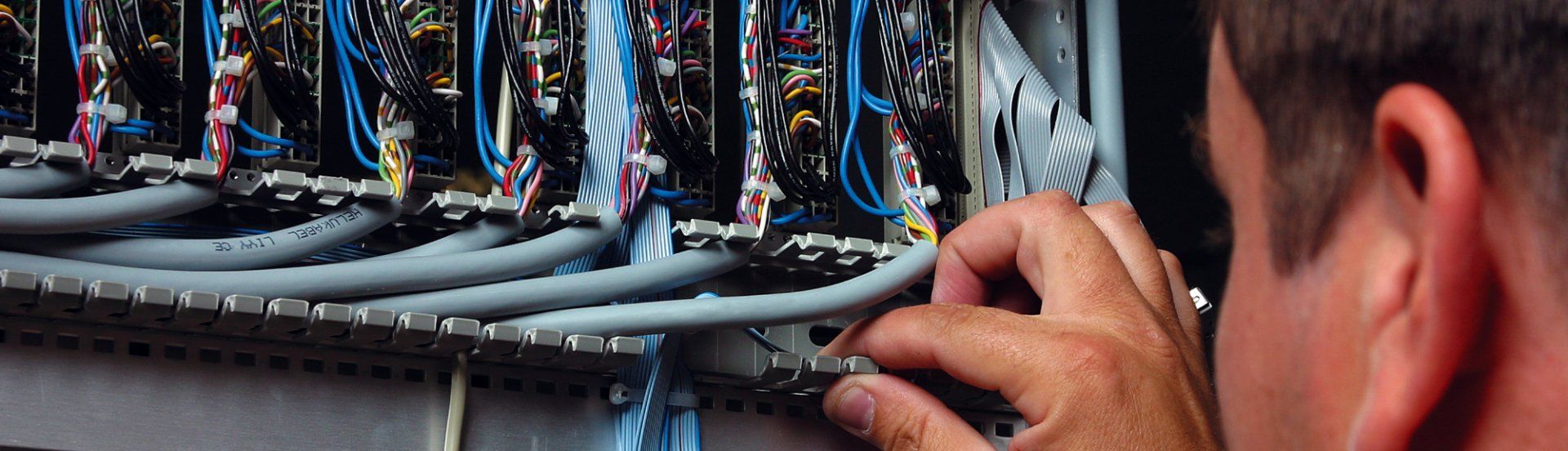

So in practice, SMT is used within the manufacturing of PCB electronics. The electronic components are placed and soldered using fully automated production lines. Roughly speaking, you can divide the whole process into three steps:

- A custom-made paste stencil is used to apply solder paste to the locations where the components will be placed on the board.

- Then the components are placed on the PCB fully automatically via SMD stations.

- After placing the components, the assembled circuit board goes through a pass-through oven so that the solder paste cures and the components are secured in place.

The benefits of SMT

Surface Mount technology has a number of advantages. Not only the volume of electronic components but also the geometric dimension can be many times smaller than with continuous components. Another advantage is the high signal transmission rate. If the PCB is assembled on all sides, an assembly density of 5-5-20 solder joints per square centimeter can be achieved. An additional advantage is a high-frequency effect, as there are no leads or they are very short. This reduces RF interference and reduces distribution parameters. The SMT technology is ideal for automatic production, thereby also improving yield and product efficiency. Other advantages of SMT technology are:

- Fewer or no holes needed in the circuit board for mounting components

- There is lower resistance and inductance at a joint.

- There are lower initial costs and less time to set everything up for mass production. This is possible because automated production lines are used.

- Higher component density, many more compounds per component possible.

- Components can be placed on either side of the circuit board.

- Under shock and vibration conditions, improved mechanical performance is possible.

Choose Confed. Choose fast, reliable and quality.

Got curious?

Have you become curious about what we can do for you in this area? We would like to invite you to contact us. This can easily be done by phone or via our general email address. You can also send us a request via the contact page and we will get back to you as soon as possible.

Contact via:

info@confed.eu or tel: +31(0) 33 454 1340